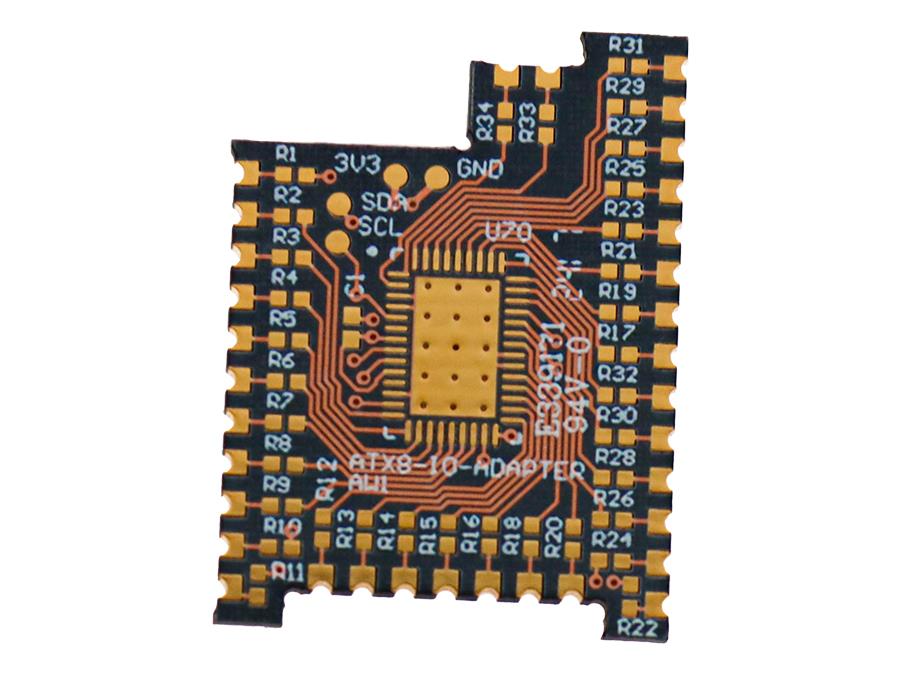

FR4 Black Core Material

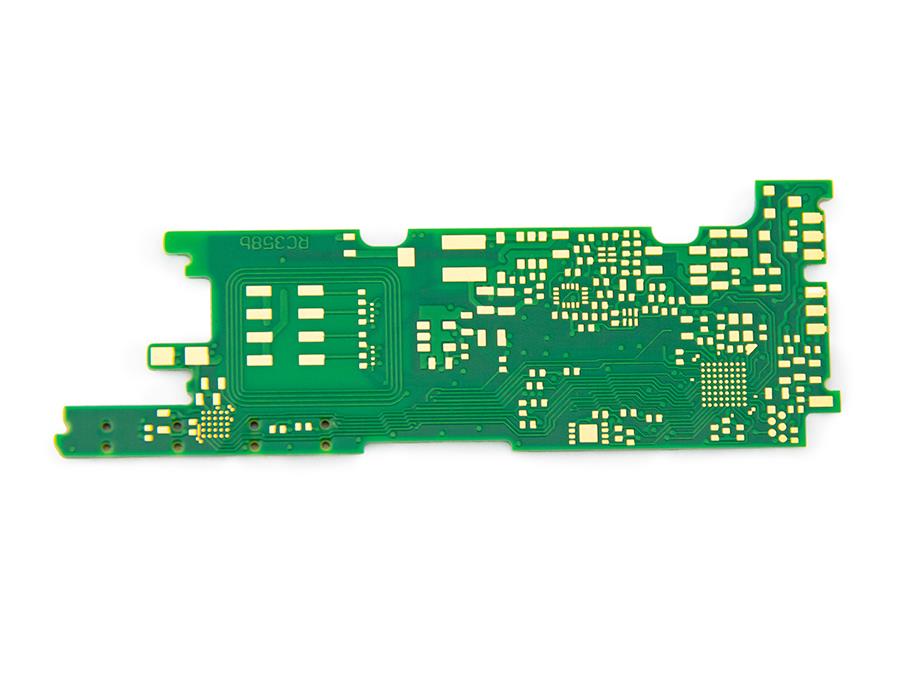

Most of the PCBs we usually see are rigid PCBs

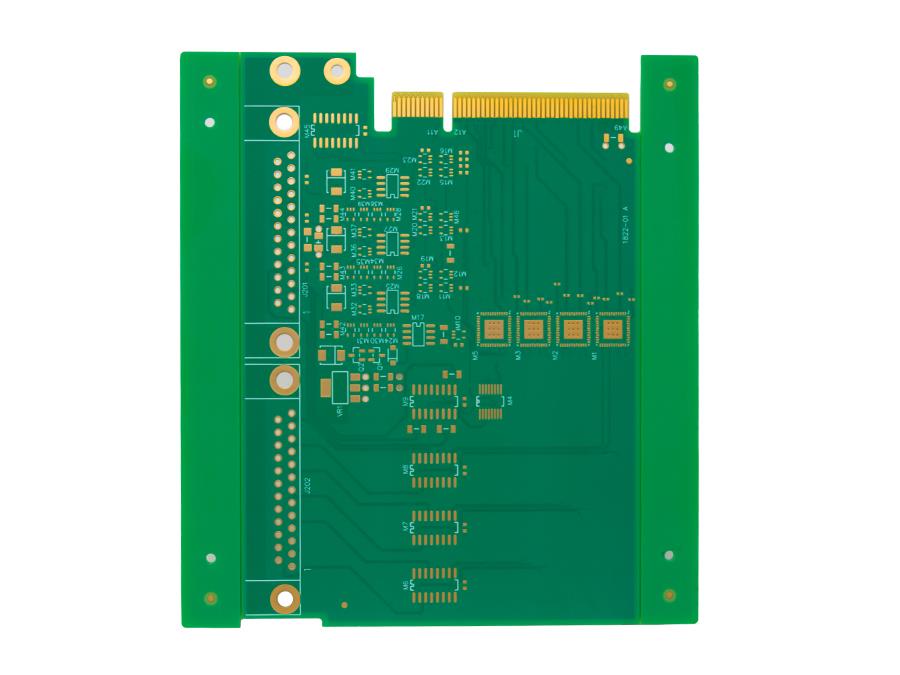

Rigid PCB

Material: FR4 Black Core Material

Finish treatment: Immersion Gold

Copper thickness: 1/1

Why Choose Us?

Professional Technical Team

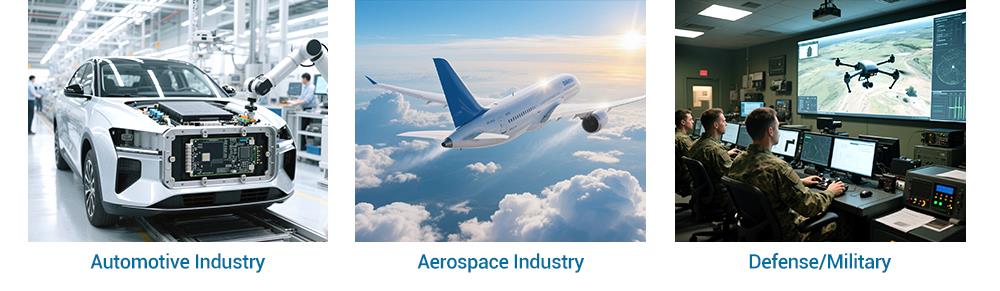

We have an experienced professional technical team with profound professional knowledge and rich practical experience in PCB design, material research and development, and manufacturing processes. Team members work closely together and constantly explore and innovate to provide personalized solutions according to customers' needs, ensuring that the product can meet customers' expectations in terms of performance and quality.

Customized Services

We can provide comprehensive customized services according to customers' different needs. Whether it's the size, number of layers, functional module design of the PCB, or material selection, surface treatment process, etc., we can tailor - make them for customers. We will communicate in depth with customers to understand the application scenarios and special requirements of their products and create the most suitable PCB solutions for customers to meet diverse market demands.

Strict Quality Control

We have established a complete quality control system. Every link, from raw material procurement to production processing and finished product inspection, undergoes strict quality inspection. Advanced testing equipment, such as automated optical inspection (AOI) and X - ray inspection, is used to comprehensively test the appearance, internal structure, and electrical performance of the PCB, ensuring that each PCB meets high - quality standards and providing customers with reliable products.

Advanced PCB Capabilities:

|

No. |

Category |

Process capability parameter |

| 1 |

Board Type |

Rigid PCB |

| 2 |

Base Material |

FR4 |

| 3 | Number of Layers | 1-50 Layers |

| 4 |

Min Trace Width/Spacing Inner Layer |

2/ 2mil |

| 5 |

Min trace width/spacing Outer Layer |

2.5/ 2.5mil |

| 6 |

Finished Copper Thickness |

0.5-8 oz |

| 7 |

Min Spacing Between Hole to Inner Layer Conductor |

7mil |

| 8 |

Min Spacing Between Hole to Outer Layer Conductor |

6mil |

| 9 |

Min Annular Ring for Component Hole |

5mil |

| 10 |

Min Annular Ring for Via |

3mil |

| 11 |

Min BGA Pitch |

0.2mil |

| 12 |

Min BGA Diameter |

8mil |

| 13 |

Min Hole Size |

0.15mm(CNC)|0.1mm(Laser Blind) |

| 14 |

Max Aspect Ratio |

14:1 |

| 15 |

Solder mask / Circuit Processing Method |

Film | LDI |

| 16 |

Min Solder mask Bridge Width |

3mil |

| 17 |

Min Thickness for Insulating Layer |

2mil |

| 18 |

Max PCB size |

600*700mm |

| 19 |

HDI & Special Type PCB |

HDI(1-3 steps), Buried capacitance, High frequency mix-pressing (2-14 layers) & resistance, etc. |

| 20 |

Surface Finish |

HASL, HASL lead free, Immersion gold(ENIG), Immersion Tin, OSP, Immersion Silver(Ag), Plating Hard Gold |

-

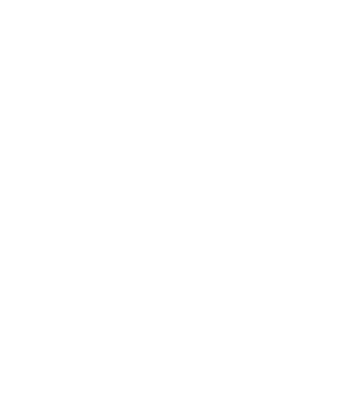

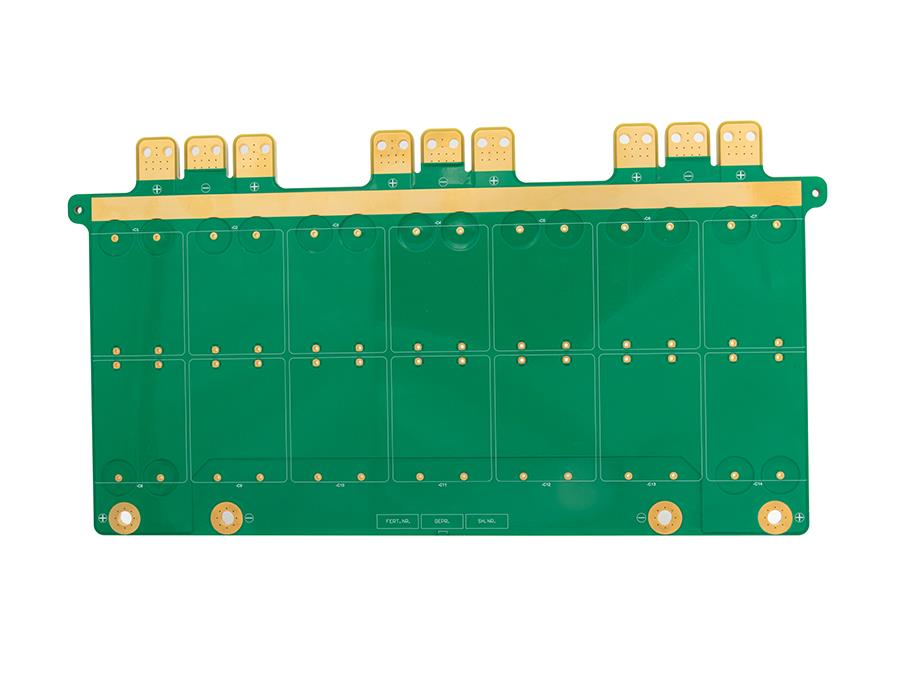

Thick Copper PCB 6OZ

Board thickness: 1.6mm Solder mask: Green solder mask Finish treatment: Immersion Gold Counterbored holes (Countersink holes)

-

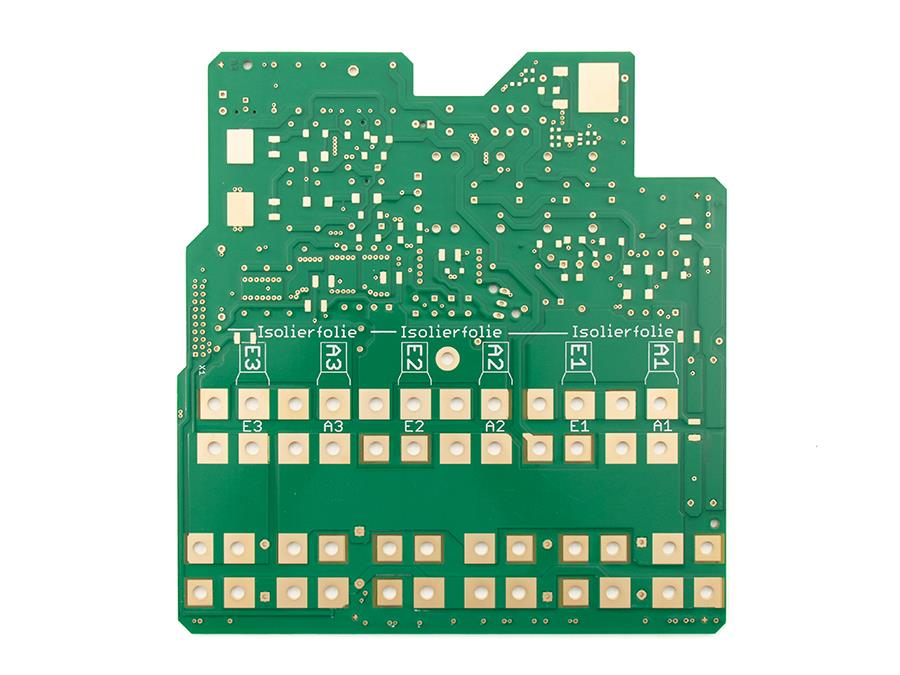

6 Layers FR4 1.6 1OZ blue oil white text nickel palladium gold

Multilayer PCB boards are suitable for complex devices with a large number of components and circuits in complex design. Material: FR4 Finish treatment: Immersion Gold Copper thickness: 1oz Surface Treatment: Immersion Gold/OSP/HASL Solder Mask Col

-

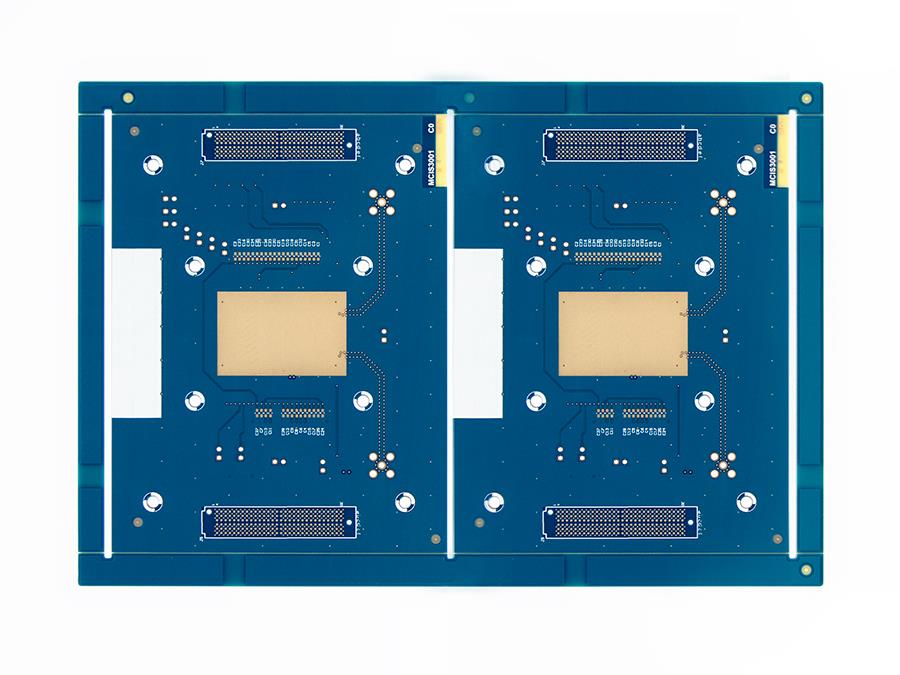

Multilayer PCB with Resin Plugging and Electroplating Filling

Multilayer PCB boards are suitable for complex devices with a large number of components and circuits in complex design. Material: FR4 TG150 Finish treatment: Immersion Gold Copper thickness: 1/1/1/1/1/1/1/1/1/1 IPC Class 3; Hole Copper: 25 μm;

-

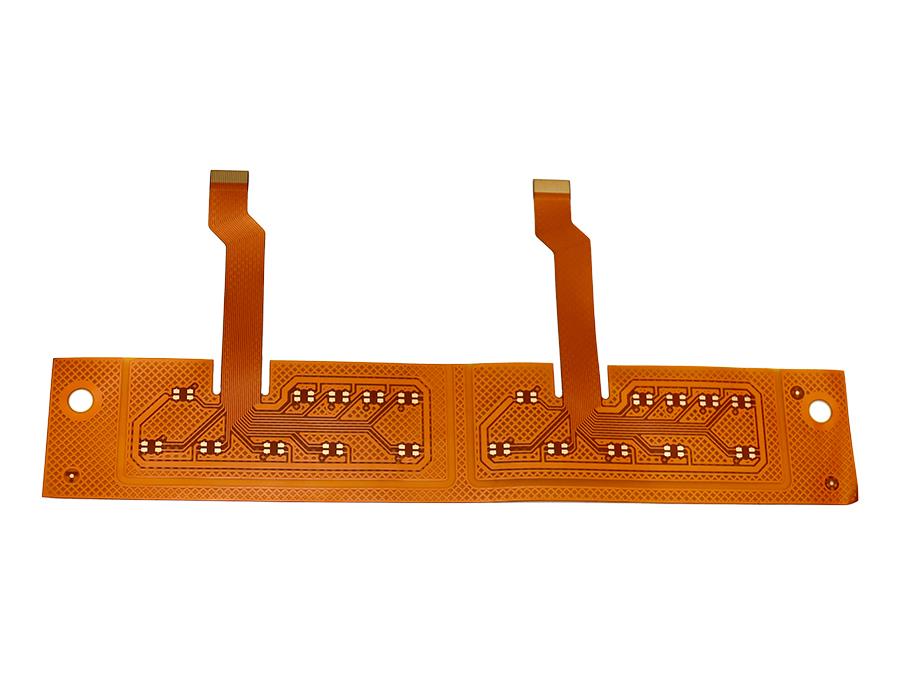

4 Layers FlexBlack Stiffeners

Flexible printed circuit boards can withstand bending, twisting and folding, and have strong adaptability for small devices. Base Material: Flex PI Surface Finishing: ENIG 2U" Copper Thickness: 35/35/35/35μm LaserVia Size: 0.1mm

-

Double Sided Green Solder Mask ENIG

Multilayer PCB boards are suitable for complex devices with a large number of components and circuits in complex design. Material: FR-4 TG150 1.51mm Finish treatment: ENIG 2U'' Copper thickness: 1/H/H/H/H/H/H/H/H/H/H/1

-

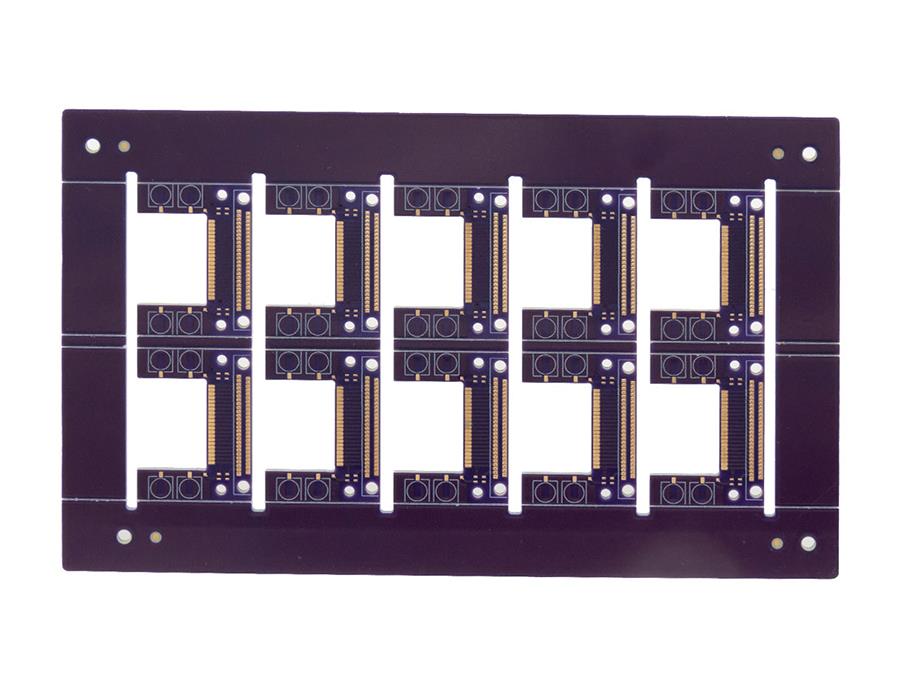

Purple Solder Mask ENEPIG

Material: Suggestion FR-4 1.2mm Finish treatment: Palladium-gold (without nickel) Copper thickness: 1/1/1/1 Solder Mask Color: Double-sided purple

-

4 Layers Thick copper PCB

The thick copper PCB has excellent extension performance, high temperature, low temperature, and corrosion resistance, allowing electronic equipment products to have a longer service life. Board thickness: 4.0mm Copper thickness: 7/6/6/7 Finish treatm

-

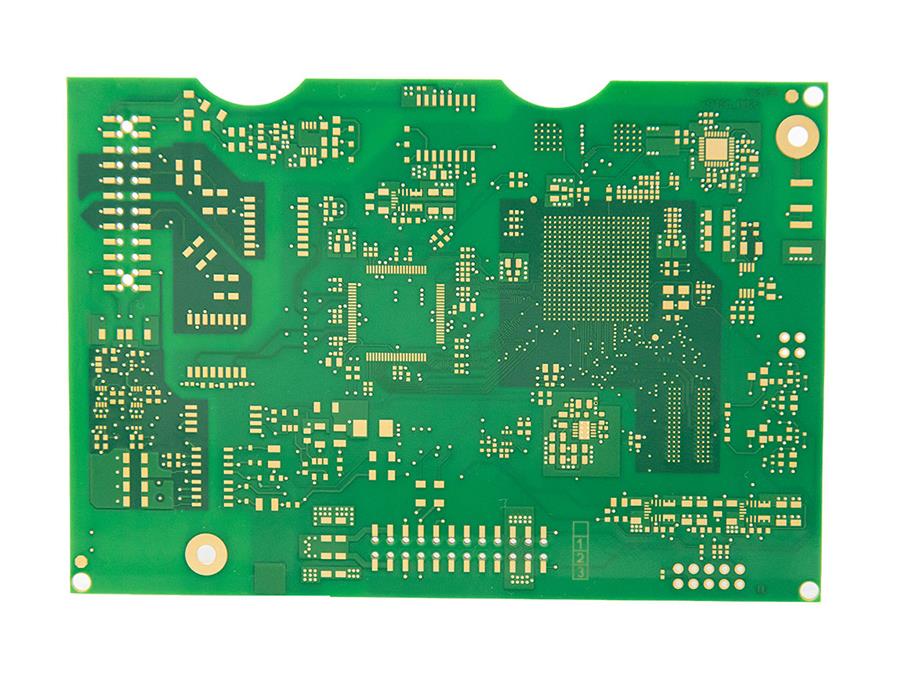

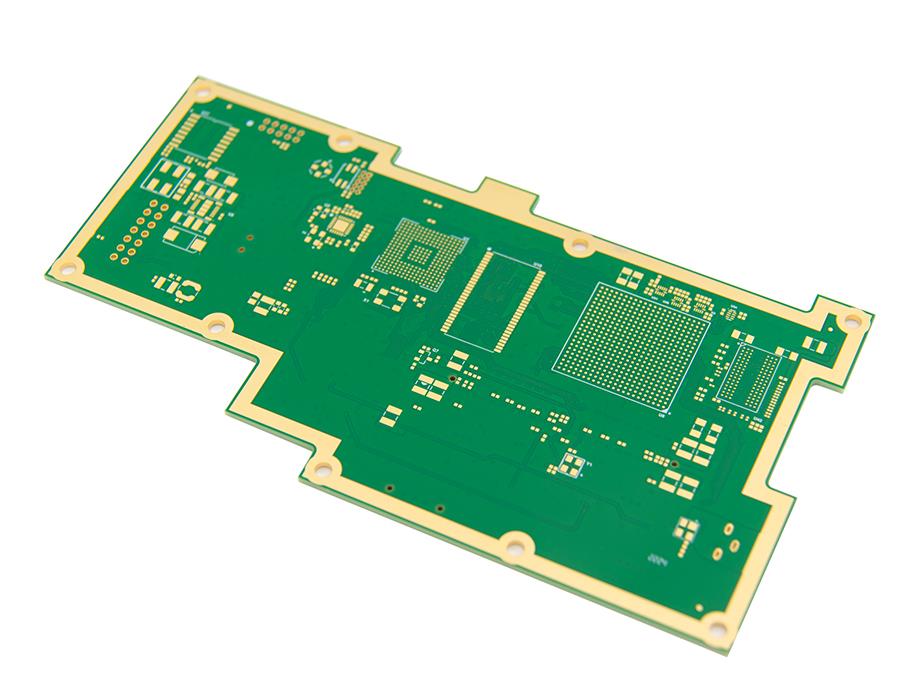

High-precision high-layer PCB, made of FR-4 TG150 material

Rigid printed circuit board Most of the PCBs we usually see are rigid PCBs Material: FR4 TG150 Finish treatment: Immersion Gold Copper thickness: 1/1/1/1/1/1 layer spans: 1–2 / 4–5 / 5–6

-

12 Layers multilayer PCB

Material: FR-4 TG135 Copper thickness: 1/H/H/H/H/H/H/H/H/H/H/1 Finish treatment: Immersion Gold Via tenting; Hole copper: 25.4μm; Solder mask thickness: 20.32μm; Impedance;

-

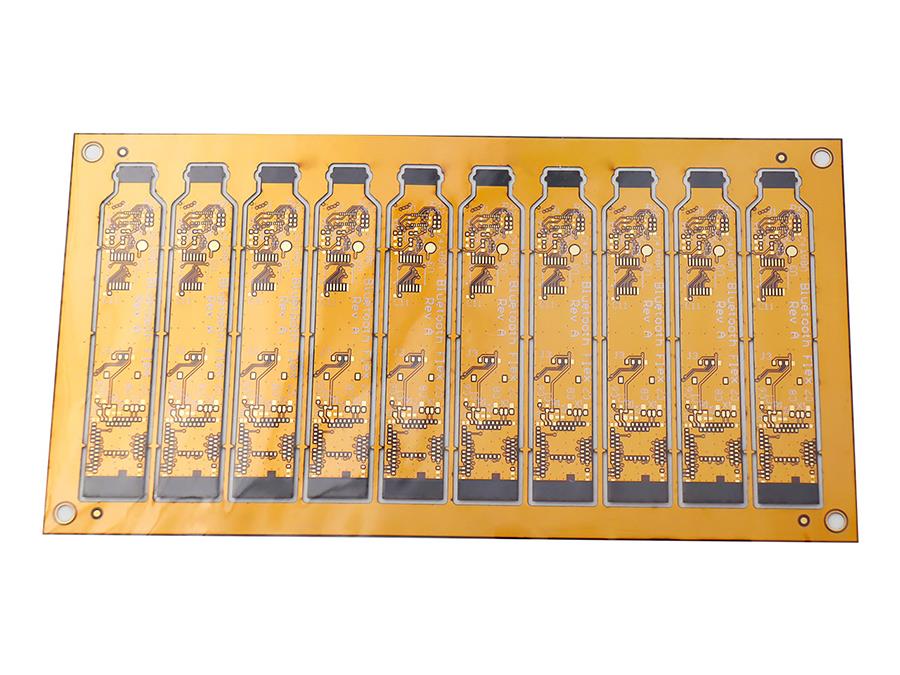

Flexible PCB with 2μ'' Immersion Gold

Flexible printed circuit boards can withstand bending, twisting and folding, and have strong adaptability for small devices. Flexible PCB Material: Flex PI surface treatment: Immersion Gold Copper thickness: 0.5/0.5 board thickness: 0.1mm

-

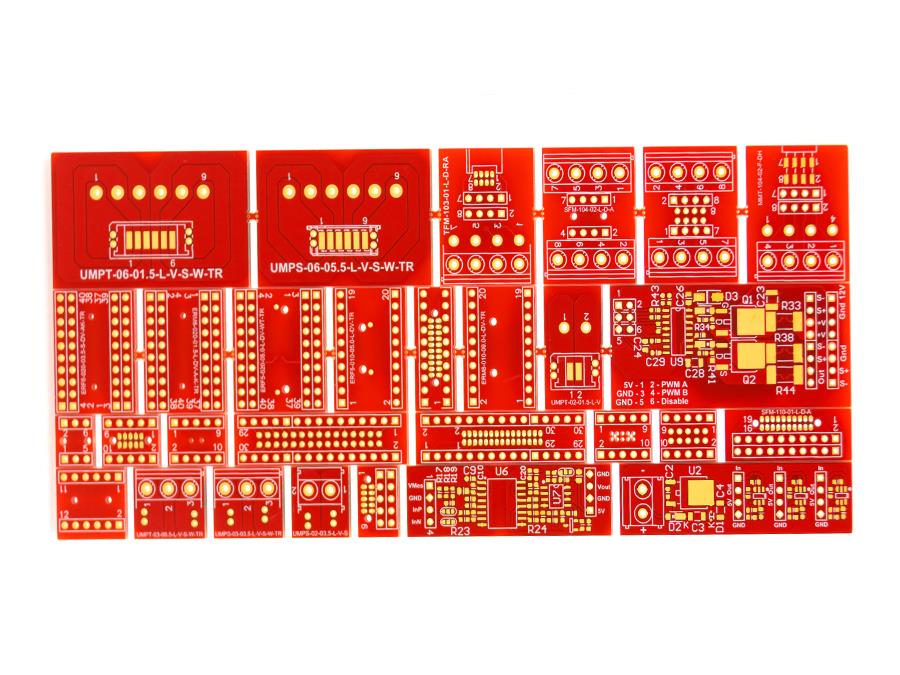

Diverse Paneling Designs Resin Plugging & Electroplated Filling

Rigid printed circuit board Most of the PCBs we usually see are rigid PCBs Material: FR4 Finish treatment: Immersion Gold Copper thickness: 1.5/1.5 Number of Combined Models in Multi-Model Merging: 29

-

4 layers Gold finger bevel edge

Material: FR-4 Finish treatment: Immersion Gold Copper thickness: 1/1/1/1 Gold finger bevel edge; Hole copper: 25μm; Impedance;

PCB Capabilities

PCBA Capabilities

SMD Stencil

Printed Circuit Boards

Product Show

Contact Us!

Our customer serviceready for your PCB

+86 18923428751

sales@hycxpcba.com