Who We Are?

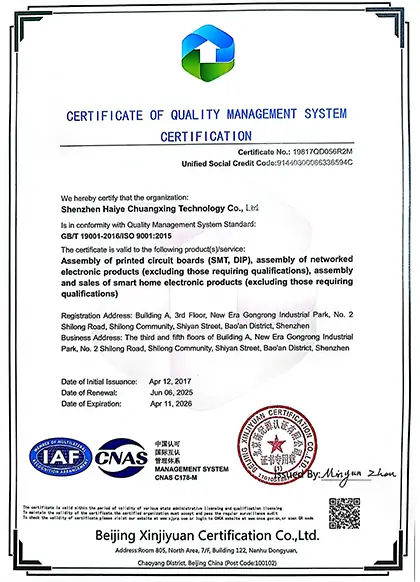

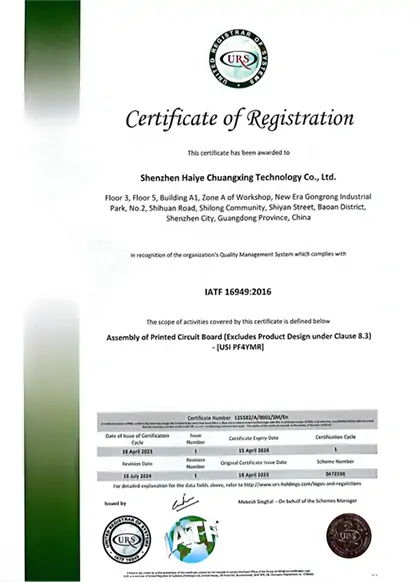

HYCXPCBA, a one-stop Chinese PCB & PCBA manufacturing factory since 2013. ISO9001, IATF16949, ISO14001, ISO13485, Rohs certificated.

As an EMS manufacturer, our service includes:

- PCB Design

- Components sourcing worldwide

- PCB Manufacturing

- PCB Assembly Manufacturing (SMT and DIP Assembly)

- Box Build/Finished Products Assembly

- Testing

No MOQ requirement, no high starting cost, your any OEM and ODM orders are all welcomed. Welcome to visit our factory and contact us for new projects!

Our Services

PCB Manufacturing

From single-sided boards to 16-layer high-density boards, we support a variety of materials and technical requirements.

- ✓ Rigid & Flexible PCBs

- ✓ HDI Technology

- ✓ Impedance Control

- ✓ ENIG/OSP/HASL Finishing

PCBA Assembly

Full assembly services including SMT patch, DIP plug-in, and BGA soldering for all volumes from 1 to 100,000+.

- ✓ SMT Assembly (0402/0201)

- ✓ Through-Hole Assembly

- ✓ Mixed Technology

- ✓ Conformal Coating

Component Sourcing

Managing your entire component lifecycle—from a single part to a complete Bill of Material (BOM).

- ✓ 10+ years of experience

- ✓ 100% sourcing from authorized distributors

- ✓ 100% New original guarantee

- ✓ 7/24 live sales & tech support

Expedited Services

Expedited service is available for all projects, including PCB fabrication, PCBA, and components.

- ✓ PCB

- ✓ PCBA

- ✓ Imported Components

- ✓ Domestic Components

Corporate Values & Cooperation Philosophy

We are grounded in technology and regard quality as our lifeblood, continuously striving for excellence. We firmly believe that exceptional cooperative relationships are built on trust, communication, and mutual growth.

Inside HYCXPCBA Factory

Electronic Products Design

Self-developed MES

Functional Testing

Overall Overview Of The Factory

Parts Procurement

Test Assembly

Our Certificates

We have obtained various certifications to ensure the quality of our products and services. Our factory is equipped with advanced testing equipment and strictly follows international standards to provide customers with reliable products.