New here ? Getting $50 coupon

Supports components down to 01005 size, delivering 95,000 CPH at ±0.035mm accuracy.Capable of handling diverse component types, its intelligent features boost productivity.

Quote Now

Sized 4420*1420*1750, suits medium - large PCBs. Efficient fluxing, preheating, wave soldering & cooling enable stable batch through - hole soldering, boosting efficiency and cutting costs.

Quote Now

With dimensions of 7550*1650*15300, features precise temperature control, nitrogen-filled anti-oxidation, improves soldering quality, and 3 units boost efficient production.

Quote Now

With a 350*300 cutting size , it’s precise and efficient, suitable for multiple scenarios. 3 units boost the production line, quickly separating PCBs, reducing costs, improving efficiency and ensuring yield.

Quote Now

Achieves 99.9% counting accuracy for 01005 components (0.4×0.2mm) through rapid non-destructive scanning.Supports multi-storage support, solder inspection, intelligent & efficient.

Quote Now

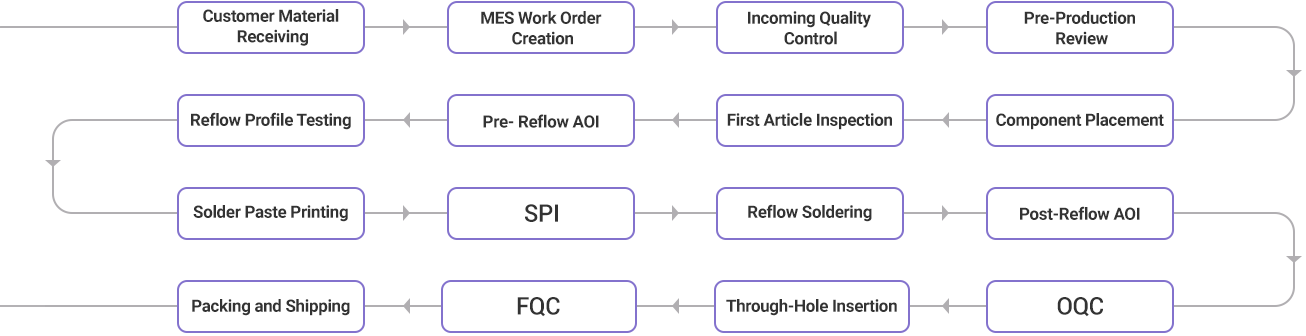

Our independently engineered Multi-module IoT System integrates an intelligent quote engine with real-time production analytics, achieving 30% faster order processing and ongoing cost optimization across the PCB supply chain.

Quote Now

We maintain 40+ certified component categories featuring 200,000+ authentic products sourced exclusively from authorized distributors, supplemented by our white-glove procurement concierge service.

Quote Now